How important are concrete admixture defoamer?

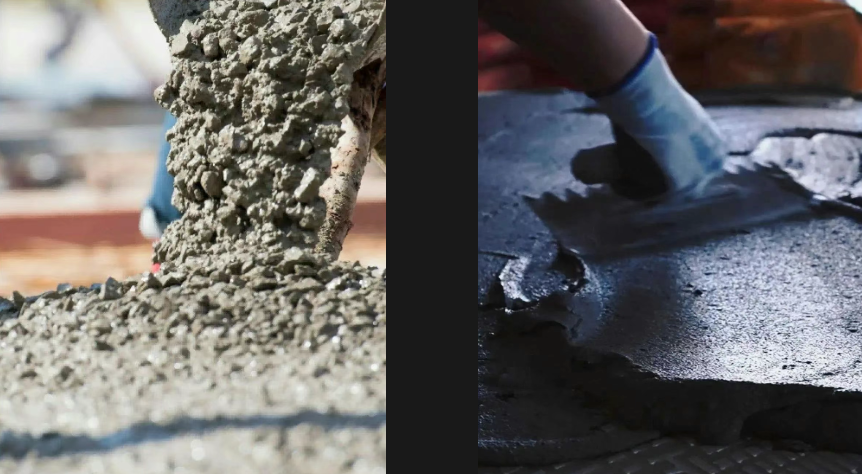

In the concrete admixture industry, when mentioning “polycarboxylic acid superplasticizers,” everyone knows that they are currently the most widely used and superior type of high-performance superplasticizers. However, in actual production processes, many manufacturers have been plagued by a persistent issue during the synthesis and use of polycarboxylic acid superplasticizers—excessive foaming!

Don't underestimate these foams; they not only affect product stability but also directly impact customer experience and can even affect the final quality of the concrete. To solve this problem, defoamers are the key.

Why does polycarboxylic acid superplasticizer tend to foam?

1. Foaming during the synthesis process The conventional synthesis pathway for polycarboxylic acid superplasticizers involves polymerization in an aqueous phase using large monomers (such as TPEG/HPEG), with the addition of various initiators, neutralizers, chain transfer agents, etc. During this process, vigorous stirring, high temperatures, and intense reactions can easily generate a large amount of foam.

2. Foaming in finished product applications Even if foam control is properly managed during production, if the defoaming system is poorly designed, customers may encounter issues such as “unstable slump” or “foaming affecting strength” when using the product at concrete sites.

What are the hazards of foaming in polycarboxylic acid water-reducing agents?

1. Material overflow: Foam spills over during mixing and reaction, resulting in raw material loss; unstable indicators with high air content affect product density and solid content measurement;

2. Poor user experience: Excessive foam during customer use leads to rapid loss of slump;

3. Difficulty in filling: Excessive foam can lead to incomplete filling of containers or improper sealing;

4. Storage degradation: Foam traps air, accelerating oxidation and promoting bacterial growth.

These issues not only increase production management complexity but also directly impact product sales and customer satisfaction.

Concrete Admixture Defoamer Solution

1. High Dispersibility: The concrete admixture defoamer can quickly and uniformly distribute in the water-reducing agent, without oil separation or layering;

2. Long-lasting Foam Suppression: The concrete admixture defoamer rapidly suppresses foam during the mixing process and maintains stable foam suppression throughout the storage period;

3. High Compatibility: The concrete admixture defoamer does not affect the transparency, appearance, or stability of the finished product;

4. No Precipitation: Concrete admixture defoamers do not cause turbidity or precipitation, making them suitable for conventional filling processes;

5. Cost-Effective: Concrete admixture defoamers require low addition rates, provide stable performance, and reduce waste.

Foam Suppressant Usage Recommendations

✅ Thoroughly mix the defoamer before use. Some products can be diluted before addition to improve dispersion.

✅ It is recommended to add the defoamer at the beginning of the reaction to facilitate overall foam control.

✅ Avoid adding excessive amounts of defoamer, as this may cause oil separation or inhibit the normal mixing process.

✅ Compatibility testing with polycarboxylic acid systems is recommended to be conducted in advance through small-scale trials.

About RISE

Although foam may seem insignificant, it can have a real impact on industrial production. Choosing the right defoamer can not only improve product quality but also optimize the entire production process, reducing unnecessary waste and risks.

We can also provide customers with customized formulation recommendations, tailoring product recommendations based on raw material types, production processes, temperature conditions, and other factors.

If you are also facing foam-related issues in your production process, feel free to leave a message or contact us via our backend. We are happy to share more industry insights and sample recommendations.