Application and development of defoamer in the paper industry

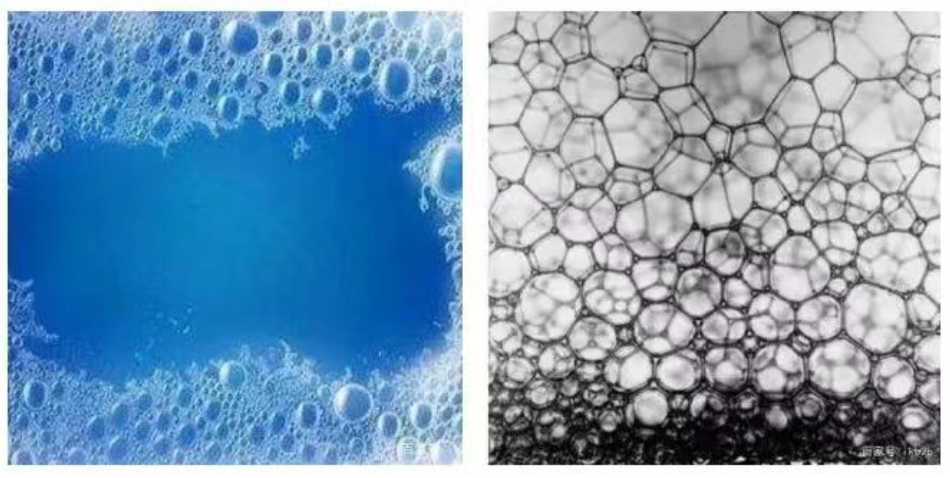

Foam is a crucial problem that often occurs in the pulp and paper production process. In the production process, improper foam control will seriously affect the implementation of pulp and paper process conditions and the normal operation of equipment, resulting in lower product yield and quality. In the pulping process, the generation and existence of foam will seriously hinder the normal operation of pulp washing, screening, bleaching and pulping process. In the papermaking process, the foam problem has a greater impact on the implementation of process conditions in the pulp flow and dewatering molding sections, and directly affects the quality of paper.

The most direct and effective measure to control foam is to add a suitable defoamer.

At present, the pulp and paper industry to control the foam methods are mainly physical and chemical methods. Physical method is to improve the bubble liquid membrane at both ends of the gas transmission rate to promote the bubble film discharge, so that the foam attenuation factor is greater than the stabilizing factor, thus reducing the number of bubbles, mainly including the placement of baffle or screen, high-speed centrifugation, steam and pressurization and decompression, etc.. Chemical method includes chemical reaction method and adding antifoaming agent method, in which the chemical reaction method is to reduce the concentration of the foaming agent in the foaming system through the chemical reaction between the specific reagent and the foaming agent, so as to promote the rupture of the foam; adding antifoaming agent can change the local surface tension of the bubbles to achieve the purpose of antifoaming.

Although the physical method is environmentally friendly and can be reused, but only a short time to remove the surface foam, it is difficult to eliminate a large number of fine foam, which is affected by environmental factors, but also increase the paper enterprise equipment investment and maintenance costs. The chemical reaction method in the actual application of the foaming agent before the need to determine the composition, and the addition of reagents and foaming agent to produce insoluble substances will be harmful to the equipment.

Production practice has proved that the use of defoamers to control foam is the most cost-effective measures, the method does not need to change the original production process, but also do not need a lot of investment in equipment and maintenance costs, the effect is ideal, easy to operate, has been widely used in the pulp and paper industry With the continuous expansion of the market of the pulp and paper industry, the related chemical additives market will continue to develop. Global paper mills are changing from acidic to alkaline paper making, and alkaline paper making is operated under a closed water circulation system, which will increase the use of defoamers and promote the development of defoamer market. Experts predict that the defoamer market in China will continue to grow at a rate of more than 4% in the last five years.

RISE new paper making defoamer antifoam AF-2200

DEFOAMER CHARACTERISTICS.

RISE defoamer antifoam AF-2200 is mainly designed for the paper making industry, the use of this product can effectively control the pulp, foam overflow and improve the quality of paper making. Defoamer AF-2200 is widely used in paper making system to eliminate foam, and can also be used in paper making sewage treatment, antifreeze, distillation system to eliminate foam.

SPECIAL PROPERTIES OF DEFOAMER

● Good dispersion in pulp, rapid defoaming.

● Low dosage of antifoam agent, high efficiency.

● Antifoam is non-toxic and odorless, which is conducive to production safety.

● Unique anti-foaming effect, conducive to the discharge of white water.

● It does not affect the sizing effect.

Looking forward to communicating with you, we provide free samples for your testing!