Silicone emulsion defoamer: Easily solve foam problems

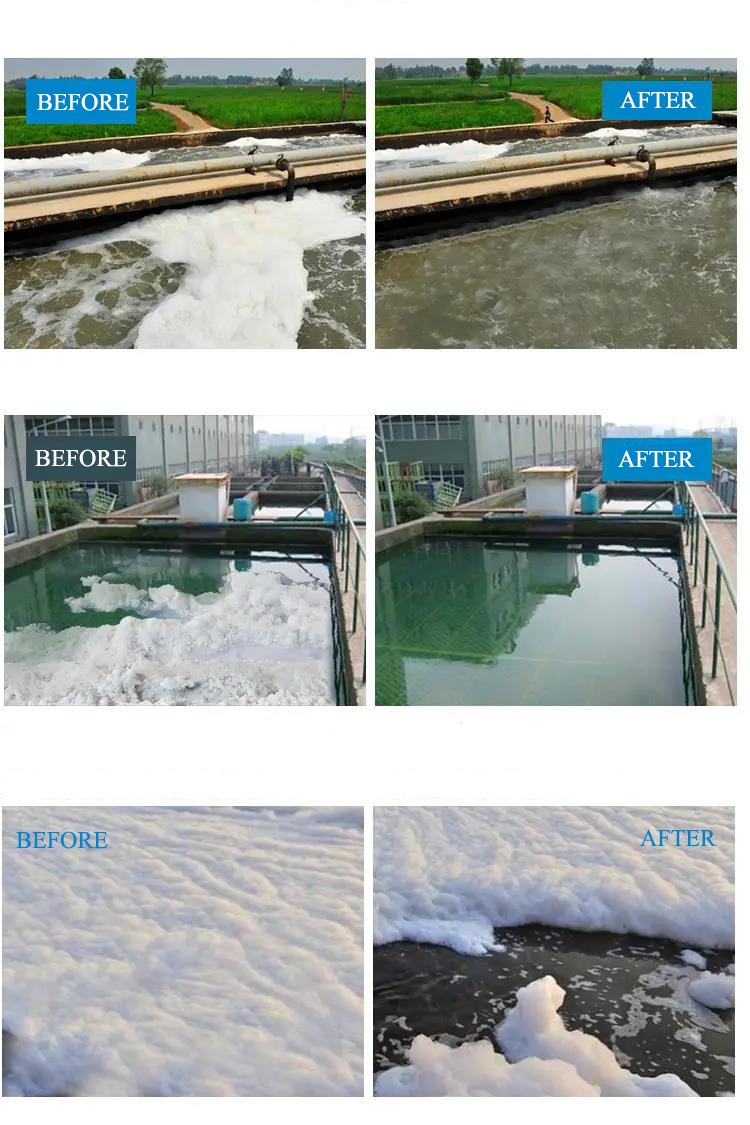

In industrial production, foam is often a headache—it can affect production efficiency, reduce product quality, and even cause safety hazards. Silicone emulsion defoamer is the “powerful weapon” for solving these problems. As the most widely used and largest member of the silicone defoamer family, silicone emulsion defoamer play an irreplaceable role in many industries with their unique structure and excellent performance.

Silicone emulsion defoamers are mostly oil-in-water (O/W) emulsions, which simply means that “oil droplets are dispersed in water”—water is the continuous flowing “ocean,” and silicone oil is the “islands” dispersed within it. The preparation process for silicone emulsion defoamer is not complicated: first, raw materials such as silicone oil, emulsifiers, and thickeners are pre-mixed, then water is gradually added and stirred evenly, and finally the mixture is repeatedly ground in a colloid mill until a smooth emulsion of the required consistency is formed. This structure allows silicone emulsion defoamers to easily integrate into aqueous systems, laying the foundation for efficient defoaming.

When using silicone emulsion defoamers, no complicated procedures are required; simply add them directly to the foaming system for effective results. However, to ensure more stable defoaming performance and precise metering, it is generally not recommended to use concentrated emulsions exceeding 10% concentration. Instead, they are first diluted with cold water or the foaming liquid itself to a concentration below 10%. Here's a tip: When diluting the silicone emulsion defoamer, never use liquids that are too hot or too cold, as this can disrupt the emulsion structure, leading to “emulsion breakdown”—where the originally uniform emulsion separates into layers, with the silicone oil floating to the surface like oil droplets on water, significantly reducing the defoaming agent's effectiveness.

The stability of diluted silicone emulsion defoamers deteriorates over time, and prolonged storage may result in separation. Therefore, it is best to prepare and use them immediately. If short-term storage is necessary, thickening agents can be added to enhance stability. Regarding the addition method of the defoamer, it can be flexibly selected based on the production process: in batch production, the silicone emulsion defoamer can either be added in a single batch before the system starts running or added in multiple batches; in continuous production, the defoamer should be continuously or intermittently added at an appropriate location in the system to ensure that foam is suppressed as soon as it appears.

About Us

Since 2004, RISE Chemical has consistently provided high-quality, tailor-made foam control solutions for the most challenging client needs. Learn what makes RISE defoamer different

With a variety of products to choose from, we're sure one of them will be suitable for your needs. Just send email to GET FREE SAMPLES.

WhatsApp: +86 15714017827

Email: amy.lee@sy-rise.com