Application of High-Performance Defoamers in Aqueous Systems

Driven by global environmental policies and industrial upgrades, water based defoamer have found widespread application across water treatment, papermaking, oilfields, coatings and inks, adhesives, and construction chemicals. They prevent foaming during production and construction processes that can cause surface defects, diminished product performance, and reduced production efficiency. As a professional defoamer manufacturer, RuiSi Chemical provides high-performance defoaming solutions that precisely address these pain points, empowering industries to achieve high-quality production.

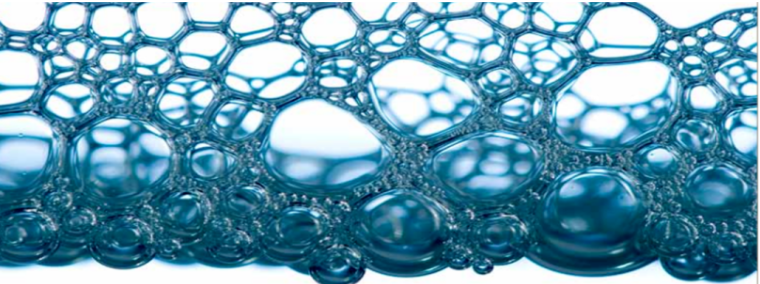

Foam in aqueous systems is a stable dispersion of gas trapped by surfactants, which reduce surface tension and prevent bubbles from breaking spontaneously. High-performance defoamers eliminate foam by interfering with foam film stability through three core mechanisms: reducing local surface tension to stretch and break films, destroying film elasticity via interactions with surfactants, and accelerating liquid drainage to collapse thin films. Advanced formulas even realize both rapid bubble-breaking and long-term suppression through precise molecular design.

Common high-performance defoamers for aqueous systems include silicone-based, mineral oil-based, polymer-based and bio-based types. Silicone-based products offer fast bubble-breaking and wide adaptability, ideal for industrial coatings; mineral oil-based ones balance cost and performance for architectural coatings; polymer-based defoamers suit zero-VOC systems with non-yellowing advantages; bio-based variants meet eco-requirements for sustainable formulations. RISE CHEMICAL’s full product portfolio covers these categories to fit diverse scenarios.

Selecting the right defoamer depends on compatibility, process adaptability and environmental performance. It must match the system to avoid defects, align with production processes (e.g., high-speed shearing or continuous production) and comply with VOC-free, APEO-free regulations. RISE CHEMICAL adheres to a "technology-driven, quality-first" concept, offering customized solutions to help customers solve foam problems efficiently, improve product quality and reduce costs.

The future of defoamers lies in high efficiency, environmental friendliness and customization. RISE CHEMICAL will keep focusing on R&D, leveraging molecular design to enhance product performance, and growing with industries in the green development wave.